Biomanufacturing Blasts Off: Collaborative Effort Sends Radiation-Resistant Samples to International Space Station

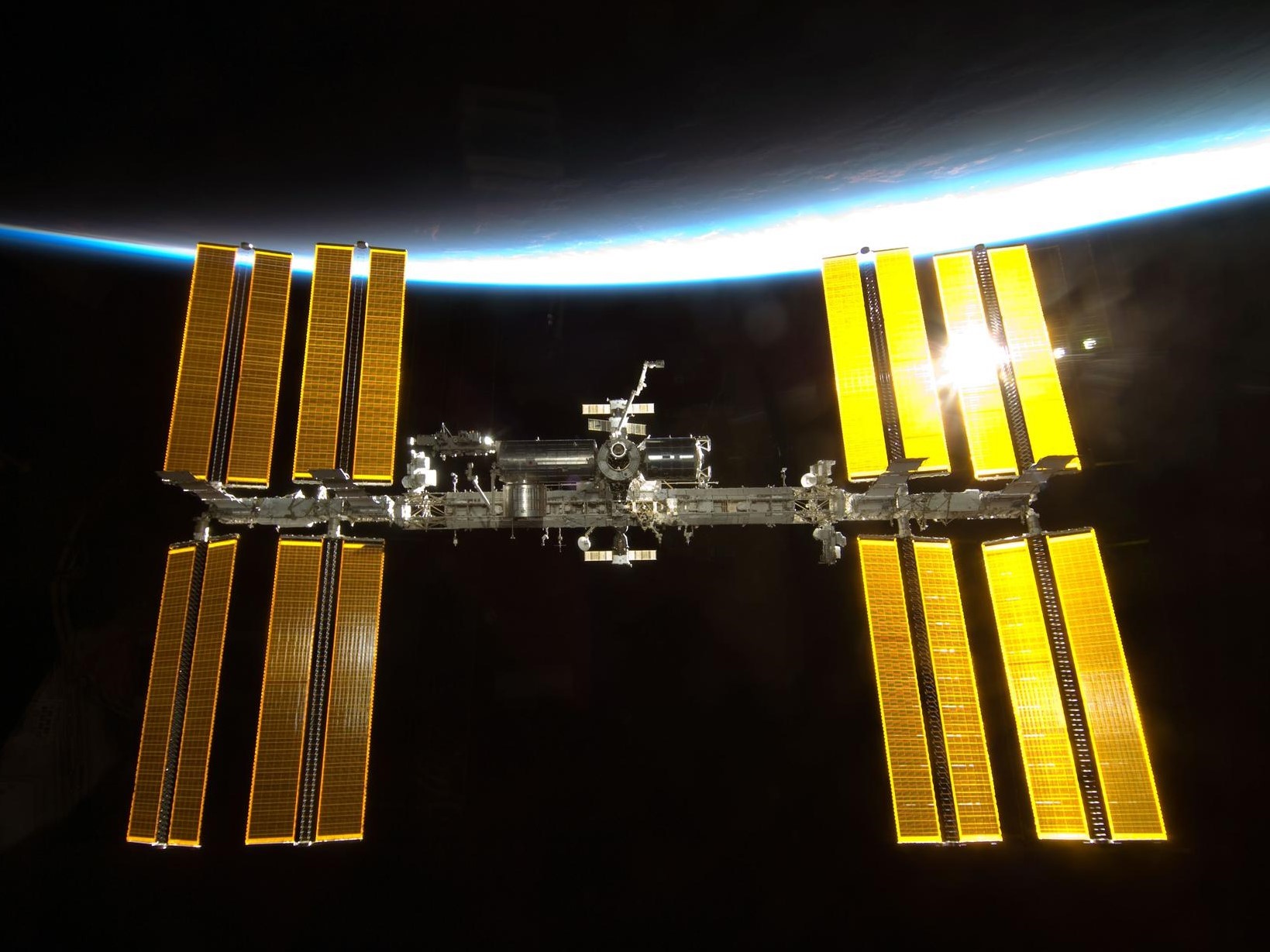

Backdropped by Earth’s horizon and the blackness of space, the International Space Station is featured in this image photographed by an STS-130 crew member as space shuttle Endeavour and the station approach each other during rendezvous and docking activities.

Engineers from The University of Texas, in collaboration with Rhodium Scientific, America’s first space biotechnology company, launched microorganisms into space. This effort is part of a Defense Advanced Research Projects Agency (DARPA) program, Biomanufacturing: Survival, Utility, and Reliability beyond Earth (B-SURE), which aims to develop a fundamental understanding of microbial capabilities for bioproduction in space.

The bacteria and yeast microorganisms, cultured in the UT lab, were assembled into spaceflight configuration by Rhodium Scientific to hitch a ride on a Northrup Grumman commercial resupply mission (NG-21) to the International Space Station. In an approach termed biomanufacturing, these microorganisms can be programmed to make a variety of molecules that can be used as food ingredients, fuels, pharmaceuticals and more.

Hal Alper, professor in the Cockrell School of Engineering’s McKetta Department of Chemical Engineering

This study aims to learn whether these microorganisms can be viable in the much harsher environment of outer space, where radiation levels are much higher than on Earth. After eight months at the International Space Station, the samples will return to Earth, where they will be analyzed for viability and production capacity.

“Cells are challenged by harsh conditions such as radiation. For example, we already know our skin cells don’t like radiation here on Earth and can mutate. The conditions are a lot worse in space,” said Hal Alper, professor in the Cockrell School of Engineering’s McKetta Department of Chemical Engineering. “For this study, we’ll be testing shelf stability and looking at how well these organisms can withstand the pressures of a space mission.”

Biomanufacturing is already a significant industry, especially in pharmaceuticals, where many critical therapies are produced from living organisms. Examples include insulin, hepatitis vaccines and several varieties of interferon.

Biomanufacturing has the chance to expand the scope of production for space missions and reduce the overall challenges of resupply missions. Tiny organisms on board could be used as factories to make the building blocks for shelter materials, food and medicine.

“Using programmed biology in space, rather than traditional manufacturing methods, enables on-demand production of materials and compounds of interest. These new mechanisms allow for the reduction of supply chain logistics, cold stowage assets, and the need for shelf stabilization in space and in remote environments on Earth – environments with limited resources,” said Olivia Gamez Holzhaus, founder and CEO of Rhodium Scientific.

While it is possible to bring these ready-made materials on the mission in the first place, the added weight also increases cost and limits the mission’s duration. On a long mission to another planet, for example, astronauts would run out of food, and medicine would expire.

These microorganisms are designed to be shelf-stable and allow the mission team to easily replenish the supply of critical food, medicine and more on demand. Biomanufacturing thus provides for the sustainable, on-demand production of essential components in space missions.

“For this specific mission, our teams are testing that shelf stability component. In practical use, we must store these cells until they’re needed, pull them out and then use them to brew any molecule required for an on-demand function with high fidelity.”

Hal AlperProfessor, Cockrell School of Engineering