Pike Robotics’ Robo-Inspectors Aim to Make Critical Infrastructure Safer

One of the most appealing aspects of robotic advancement is the ability to perform duties that aren’t safe for humans — jobs that Connor Crawford calls “dull, dirty and dangerous.”

Crawford is the CEO of Pike Robotics, which makes robots that inspect critical infrastructure, including oil and gas storage tanks, ship hulls, distillation columns and other confined and hazardous environments.

Crawford came to UT after spending nearly four years at Lockheed Martin. He received his master’s degree in mechanical engineering in 2022, and then started Pike Robotics as an extension of his research. Crawford has long sought to create products that make life safer and easier for people. Pike Robotics aims to do both, by taking people out of hazardous environments and improving the efficiency and safety of infrastructure inspections.

Pike is an all-UT company thus far. It spun out of the Nuclear and Applied Robotics Group, and all 10 team members are Longhorns, whether that be graduates, professors, advisors, etc. We sat down with Crawford to learn more about his company and his experiences building a startup.

Tell us about where the idea for Pike Robotics came from, and the company’s goals.

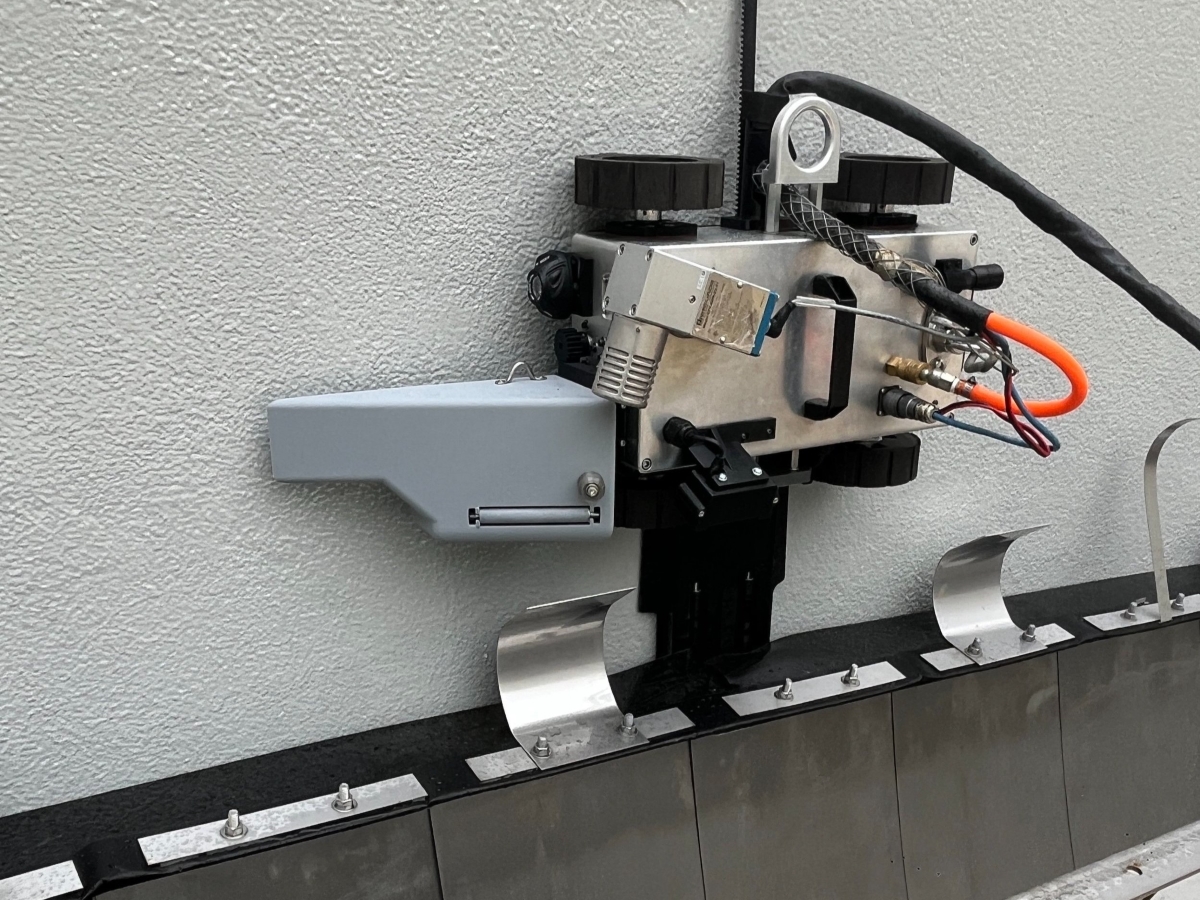

Oil and gas storage tank inspections are necessary for environmental compliance and site maintenance, but they are costly, hazardous, and inefficient. They require manual crews to enter confined spaces, exposing workers to serious risks and forcing companies to shut down operations for days or even weeks. I saw an opportunity to change that. Through multiple iterations and real-world testing, we developed a wall-crawling robotic platform designed to inspect critical infrastructure without taking it offline.

The project started within the Nuclear and Applied Robotics Group, led by Mitch Pryor, and funded by Phillips 66. Pike Robotics is driven by two key goals: to remove the necessity of placing people in hazardous environments for dangerous tasks and to provide asset owners with more actionable inspection data. With new EPA regulations increasing inspection frequency, companies need solutions that reduce downtime, improve data accuracy, and enhance safety.

What are the current challenges with these types of inspections, and how can Pike Robotics help with that?

Between 2011 and 2018, more than 1,000 workers in the United States died from confined space entry, with 205 fatalities inside storage tanks specifically. There are more than 140,000 storage tanks worldwide that require frequent manual inspections, which involve five-person crews, full tank shutdowns and exposure to toxic gases. This job is the definition of dull, dirty, and dangerous.

Pike Robotics’ Wall-Eye is the first wall-crawling robot designed for in-service tank inspections in hazardous environments. Our goal is to remove human risk entirely, eliminating the potential for severe injuries while providing cost savings and faster inspections.

What are some of the benefits of improving inspections of these types of facilities?

One of the biggest challenges with traditional tank inspections is the need to drain and degas tanks, a process that release up to 100 tons of carbon dioxide and volatile organic compound (VOC) emissions per tank turnaround. Additionally, up to 4% of stored product can be lost to evaporation due to faulty seals, contributing to both financial losses and environmental harm.

Poor data around the integrity of tank seals can also lead to increased safety risks — when seals degrade, they allow more flammable vapors to accumulate inside the tank, raising the likelihood of catastrophic lightning-induced fires, like what occurred at a refinery in Lake Charles, LA in May of 2023.

Let’s switch gears. Tell us about an influential moment/course/project/person at UT, and how it helped shape your work.

Looking back at Pike Robotics’ journey, I can say with certainty that we wouldn’t be where we are today without the support and guidance of some key people at UT Austin. Starting a robotics company is no easy task — it’s a mix of deep technical challenges, regulatory hurdles and the steep learning curve of turning research into a real business. But thanks to the right advisors and mentors, we’ve been able to navigate those challenges and build something that’s making a real impact.

One of the biggest influences has been Ashley Jennings and the team at the Texas Innovation Center. Ashley has been a rock for us, helping to bridge the gap between academic research and startup execution. Whether it was getting us in front of investors, helping us fine-tune our pitch, or simply making sure we were taking the right steps to commercialize our technology, her support has been invaluable.

Then there’s UT professors David Dalle Molle and Jim Nelson — who brought industry experience and no-nonsense advice that helped us avoid some major pitfalls. And we can’t forget the Discovery to Impact team at UT Austin. They played a massive role in helping us secure early-stage funding, without which we wouldn’t be here today. Their support ensured we had the runway to develop and refine our robotic inspection platform before bringing it to market. They also helped us navigate the SBIR grant process, IP licensing, and connect with the right stakeholders to accelerate our commercialization efforts.

The truth is, Pike Robotics started as a grad school project, but thanks to the guidance of these folks, it became something much bigger. They helped us transition from “cool research” to a company that’s actually solving a major industry problem. We’re grateful for their continued support as we scale, and we hope to pay it forward to the next generation of founders coming out of UT Austin.

What advice do you have for budding entrepreneurs at UT?

Don’t begin working on a novel solution to a problem until you know enough people will pay for and invest in it . It takes at least 100 interviews to learn enough about a problem to figure this out, and you’ll pivot your idea at least 10 times during that customer discovery process.

Once you’ve got the problem figured out, a solution in development, and a rough idea for a business model, the hard part starts. Now you need to run your company. It’s a lot like drinking from a fire hose. There’s no way to prepare for everything, and the sheer number of things you have to figure out — fundraising, product development, hiring, sales, legal — can feel overwhelming. The key is to stay focused, make decisions quickly, and keep pushing forward, even when things don’t go according to plan. Because they won’t. Plan your day the night before and start chipping away at that mountain of tasks in the morning.

Perseverance is everything. You’re going to hit roadblocks. You’ll hear “no” more times than you can count. We’ve had designs fail in the field, grant applications rejected, and potential deals fall through at the last second. But success isn’t about avoiding failure—it’s about whether you can take the hit, learn from it, and keep going. The only way to fail is to quit too soon.

That said, you can’t do it alone. Build a strong team — one that complements your skills, challenges your thinking, and shares your vision. At Pike Robotics, having the right people in the room has made all the difference. A great team won’t just help solve problems; they’ll also keep you grounded when things get tough.

And finally, take advice with a grain of salt. Everyone — from investors to mentors to random people at networking events — will have an opinion about what you should do. Listen, but don’t let it derail you. Nobody knows your business better than you do. The trick is knowing what feedback is useful and what to ignore. Trust your instincts, make the best decision you can with the information you have, and move forward.