Imagine a laser so gentle it can cradle nanoparticles, biological cells, and even drive drug-delivering microscopic vehicles to sick cells without causing harm. This isn’t science fiction; it’s a new innovation led by a team of scientists at The University of Texas at Austin.

In a world driven by nanotechnology and the quest for better drug delivery methods, optical tweezers have been a game-changer. These precision instruments use lasers to trap and manipulate minuscule objects down to the nanoscale, but their high energy requirements and potential to damage fragile materials like nanoparticles and biological cells limit their use.

Pavana Kollipara, recent Ph.D. graduate from professor Yuebing Zheng’s research group

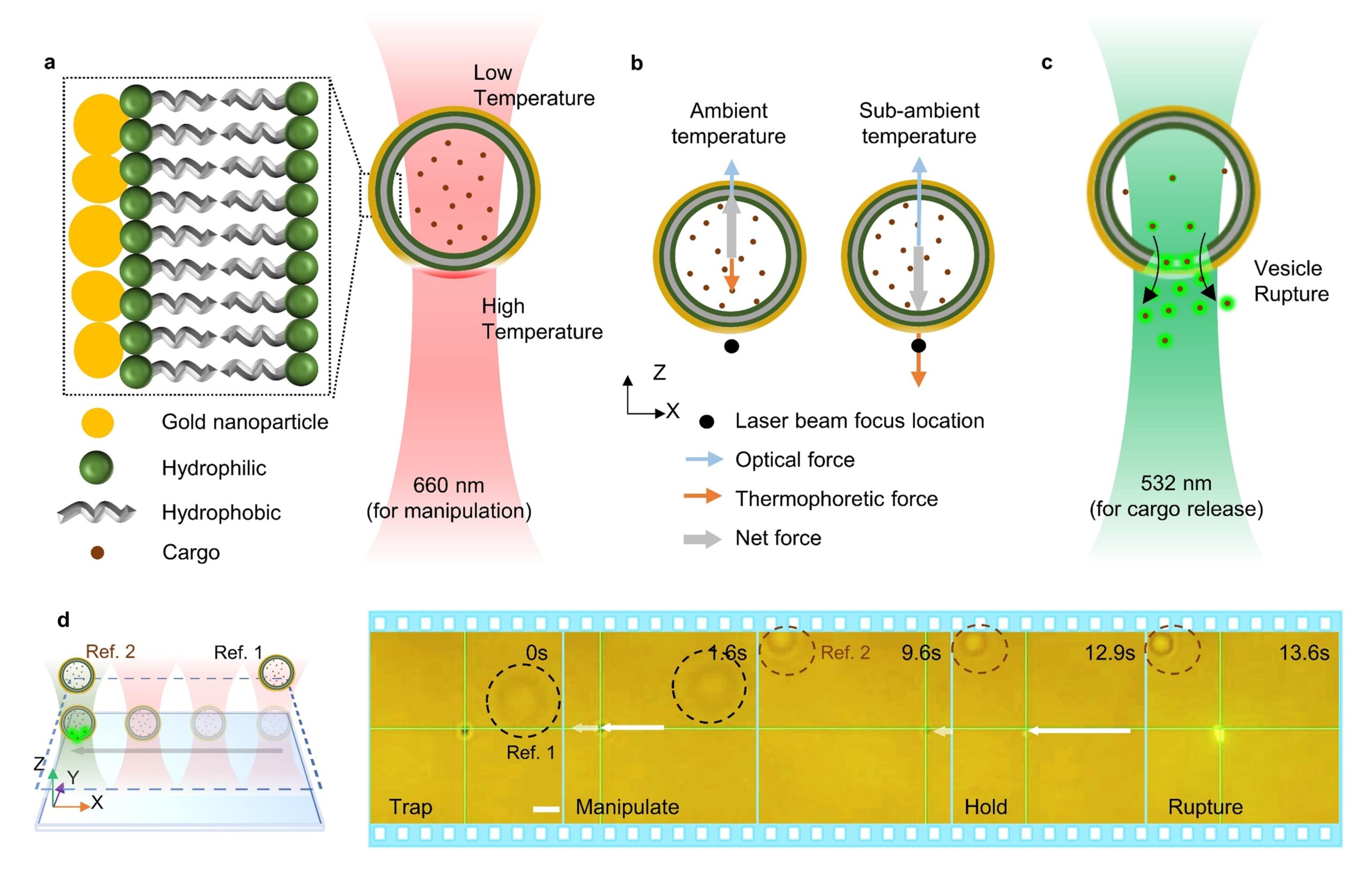

Researchers at the University of Texas at Austin have recently overcome this long-standing problem to revolutionize biotechnological applications of optical tweezers to cell surgery and drug delivery areas. The technology, called Hypothermal Opto-thermophoretic tweezers (HOTTs), uses an ingenious environmental cooling strategy combined with precise laser heating to achieve the impossible: trapping nanoparticles, cells, and drug-carrying vesicles at sub-ambient temperatures, all without causing harm and limiting their physiological conditions.

HOTTs work by harnessing a temperature gradient: they create a cool environment while using a focused laser to generate localized heating. This temperature difference creates thermophoretic forces that gently guide and manipulate objects within the laser’s grasp.

“Our work is overcoming all the current limitations of opto-thermal tweezers. By cooling the sample and combining it with laser heating, we can maintain the cell at a suitable temperature while trapping and moving it, irrespective of what the solvent or concentration is,” said Pavana Siddhartha Kollipara, a recent Ph.D. graduate from Walker Department of Mechanical Engineering professor Yuebing Zheng’s research group, who led the research recently published in Nature. “This is an important step for the industrialization of opto-thermal tweezers, pushing it into practical applications of controlled cell surgery and drug delivery.”

This research was published recently in Nature Communications. The researchers mentioned several key advantages and applications of HOTTs:

Gentle on materials: Traditional optical tweezers often damage or even destroy delicate materials, but HOTTs offer a non-invasive, low-power alternative. This clears the way to work with more sensitive materials.

Biological applications: The ability to manipulate biological cells in their native environments without disrupting their functions is key to applications in biomedical research. The gentle nature of HOTTs means researchers can now delve deeper into cell behavior and interactions without compromising cell viability, and unlike the predecessor technology, this can be achieved irrespective of the cells without inducing any damage – an important criterion for implementing the technology to practical use in the biomedical industry.

Drug delivery: Imagine precise, controlled drug delivery at the cellular level for targeted cancer therapeutics. HOTTs make this a reality by allowing scientists to manipulate plasmonic vesicles. These vesicles, coated with gold, have unique properties that can be harnessed for various medical applications. With HOTTs, scientists could precisely position these vesicles and release drugs on demand – which would present targeted drug delivery and pave the way for personalized medicine.

Surgical applications: Using HOTTs, cells can be manipulated into preset positions, and then cut open into them by the simple means of increasing laser power. By trapping human red blood cells in varying tonicities without causing damage, scientists will be able to study diseases like sickle cell anemia and malaria more effectively.

Team members include: From the Walker Department of Mechanical Engineering at UT Austin, professor Zheng, Kollipara and Hongru Ding; from the Department of Mechanical Engineering at The University of Texas at Dallas, professor Zhenpeng Qin and Xiuying Li; from the Materials Science and Engineering Program at UT, Jingang Li, Zhihan Chen and Youngsun and Suichu Huang of the Key Laboratory of Micro-Systems and Micro-Structures Manufacturing of Ministry of Education and School of Mechatronics Engineering, Harbin Institute of Technology, in China.