For engineers in the Texas Materials Institute (TMI) at The University of Texas at Austin, the allure of materials science — the study and development of new materials — is that it has so many applications and so much potential. Whether in energy, electronics, cybersecurity, medicine, transportation or manufacturing, the identification and advancement of materials can often lead to revolutionary solutions.

For engineers in the Texas Materials Institute (TMI) at The University of Texas at Austin, the allure of materials science — the study and development of new materials — is that it has so many applications and so much potential. Whether in energy, electronics, cybersecurity, medicine, transportation or manufacturing, the identification and advancement of materials can often lead to revolutionary solutions.

“Materials science is everywhere. Materials are part of our daily lives,” said Ram Manthiram, director of TMI and a mechanical engineering professor in the Cockrell School of Engineering. “It is a field that touches every industry, from construction and energy to biomedical and technology. Understanding the properties and performances of materials helps us come up with newer, lower cost, durable materials with more functionality. New materials have the potential to change the way we live.”

UT Austin established TMI in 1998 with the goals of being a first-class materials research center and enhancing the Cockrell School’s graduate program in materials science and engineering. Historically, TMI has operated in a decentralized capacity, with various facilities spread across campus. But when the Engineering Education and Research Center (EERC), the Cockrell School’s new central hub for multidisciplinary research and teaching, opens this fall, it will help bring TMI together, consolidating its shared facilities and providing a new central headquarters for its leadership and administrative staff.

More than 100 TMI researchers and their graduate students are already pushing the boundaries of materials science at separate labs across campus, but the new hub of shared facilities and tools inside the state-of-the-art EERC will be a boon to the research.

“The new space will help us showcase the world-class work that is already happening at TMI, while also giving us the opportunity to educate more students and grow our brand, influence and faculty membership,” Manthiram said.

All TMI members have appointments in the Cockrell School of Engineering or the College of Natural Sciences and conduct materials research and engineering in a variety of areas. TMI’s doctoral program accepts about 15 Ph.D. students per year.

To continue to compete with similar programs at the nation’s top engineering schools, Manthiram plans to update and add critical research equipment that will help deepen the understanding of the intricacies of materials. The new space in the EERC will also help TMI’s efforts to recruit top faculty in different areas at UT Austin, increasing its breadth and creating more collaborative opportunities for researchers to innovate.

“For nearly two decades, TMI has been innovating in energy materials, electronic materials, structural materials, soft materials and many other areas,” Manthiram said. “We are excited to have a new, dedicated space inside the EERC to address societal challenges for many decades to come.”

Inside Texas Materials Institute Labs

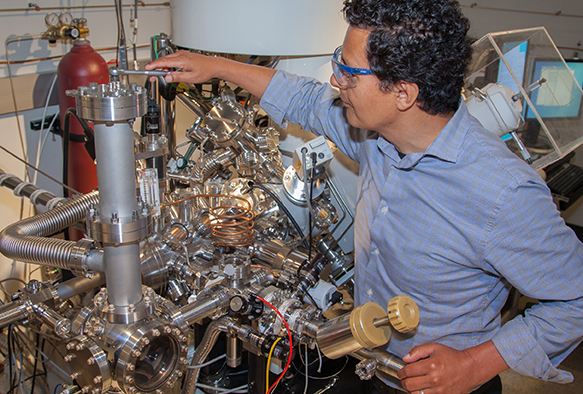

The Texas Materials Institute has a membership of more than 100 UT Austin researchers. Here, we take a look inside three of their labs:

For Donglei (Emma) Fan, materials have the potential to do amazing things on a very small scale. Fan, an associate professor of mechanical engineering, is developing innovative ways to bridge the fabrications of nanomaterials to practical applications. Her research focuses on three aspects of nanomaterials: the fabrication of various nanostructures, including 0D dots, 1D wires, 2D thin films and 3D nanosuperstructures via investigating the fundamental sciences of materials and chemistry. Recently, she developed a new approach to fabricate 3D hieratically porous thin graphite and applied it in flexible energy devices. She is an expert in investigating concepts, approaches and devices to motorize nanoparticles with ultrahigh control and precision, and then apply them in biosensors, in-vitro drug delivery and nanomachines.

“I enjoy research and consider it a great privilege to conduct research and resolve critical problems. In the field of nanomaterials and nanotechnology, great advances have already been made in fabricating nanoparticles, but there are formidable challenges for them to become practical and useful for people’s lives, so I want to address these critical issues and bridge the fabrication with these applications.” — Emma Fan

Ram Manthiram, director of the Texas Materials Institute, is working on new materials aimed at delivering lower-cost, longer-lasting, environmentally friendly batteries with high energy density for electronics, electric vehicles and renewable energy storage. Manthiram’s lab is part of the Battery500 consortium, a U.S. Department of Energy effort for developing electric vehicle batteries with a specific energy of 500 watt-hours per kilogram (more than two-and-a-half times the energy in today’s typical EV battery). The challenge with this task is the fast performance degradation of lithium batteries based on nickel-rich oxides or sulfur. With advanced characterization of the battery materials, employing TMI facilities, Manthiram and his team are making major strides toward solving these issues.

“Our work with TMI facilities has given us a lot of in-depth understanding of the nickel-rich oxide and sulfur cathode materials, and we are using that understanding to work with Battery500 consortium to achieve the goal of 500 Wh/kg." — Ram Manthiram

Guihua Yu, assistant professor of materials science and mechanical engineering, is working on several materials projects related to energy and the environment. First, he’s developing a new chemical makeup for an entirely new class of 2D materials. Typically, most 2-D materials are intrinsically made up of layered structures, so they can be exfoliated into ultra-thin nanosheets. Yu’s group is trying to develop a self-assembly strategy to synthesize a broader class of 2D materials with even, non-layered structures, and he believes the atom-thick nanosheets his lab has created can be used as a material host to store energy, opening up avenues for sodium-ion batteries or even magnesium-ion batteries. At the same time, he’s collaborating with lithium-ion battery inventor John Goodenough on redox flow batteries for large, grid-scale energy storage. Using bio-inspired organic materials, they have come up with a series of useful organic molecules that can act as both liquid and solid electrodes for high-energy batteries.

“We are testing these materials on a small scale in the lab, but we hope to partner with industry on testing some of these technologies on a larger scale. We think these are promising technologies for both portable batteries and large-scale grid storage.” — Guihua Yu