Often, engineering innovation happens in a sequence that starts with engineers developing a technology and then handing it over to designers to turn into everyday products. But Cockrell School of Engineering professor Brian Korgel and visiting fine arts professor James Sham, of George Washington University, wanted to see what would happen when a team of student engineers and artists from The University of Texas at Austin worked together from the beginning. Together, they developed a new kind of paper-based photovoltaics (PVs)— devices that convert light into electricity — that are inexpensive, portable and capable of holding enough voltage to power hand-held devices.

Often, engineering innovation happens in a sequence that starts with engineers developing a technology and then handing it over to designers to turn into everyday products. But Cockrell School of Engineering professor Brian Korgel and visiting fine arts professor James Sham, of George Washington University, wanted to see what would happen when a team of student engineers and artists from The University of Texas at Austin worked together from the beginning. Together, they developed a new kind of paper-based photovoltaics (PVs)— devices that convert light into electricity — that are inexpensive, portable and capable of holding enough voltage to power hand-held devices.

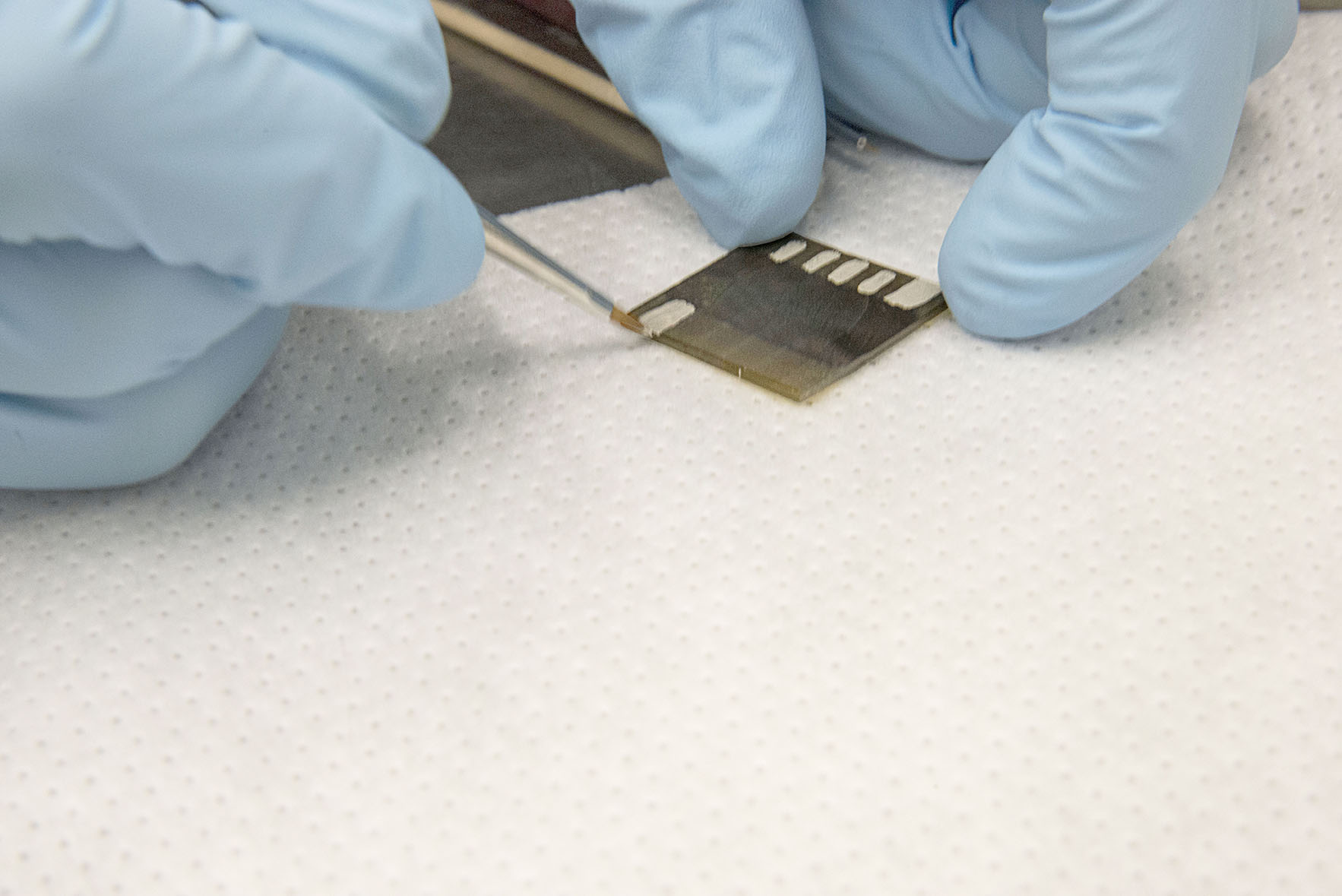

With an eye on both design and practicality, the team developed solar cells on paper that are foldable, durable and can be mounted on any type of surface. They envision their paper PVs being used for small devices, wearables adhered directly to the skin or even custom-designed wallpaper for inside and outside homes. The researchers describe their innovation in the journal ACS Energy Letters, but here are five ways their solar cell paper is smarter than other paper PVs:

-

It was made out of living organisms — The researchers’ solar paper was produced by bacteria, which makes it ecofriendly, biodegradable and easily recyclable. To build a solar cell on paper, researchers sprayed nanocrystals on a surface composed of bacterial cellulose nanofibers. Nanocellulose paper requires little more than a wet laboratory set-up, so it can be cultivated and made on-site.

-

Its electricity flows smoothly — The paper demonstrated good thermal and air stability, with power conversion efficiencies as high as 2.25 percent, the highest efficiency reported for solar cells on paper, which allows it to produce enough voltage to power a small electronic device.

-

It is super flexible and foldable — The paper solar cells retained their performance after more than 100 bending cycles to a radius as small as 5 millimeters. To compare, the smallest bending radius previously reported without considerable performance loss is 2 centimeters. The team’s paper PVs also continued to work even when folded across the active region of the device.

-

It has a uniquely textured surface — Paper made from bacterial nanocellulose has small fibers that provide a much smoother paper surface with smaller pores. Because pores can lead to short circuits in the devices, having small pores and a uniform, continuous coating is essential for optimal performance. Conventional paper and plastic films, on the other hand, are either too rough and porous, or too smooth and non-adhesive, leading to solar cells that flake off when flexed. Nanocellulose paper has the perfect combination of fiber and pore size and solar cell-layer adhesion.

-

It is design-ready — The paper PVs can withstand wrinkles and creases, while continuing to function, which could enable greater complexity and creativity in functional art or origami designs. The paper PVs can also be mounted to any type of surface for different applications. For instance, the researchers are imagining self-powering “active” labels on objects and products — think of a beverage container that can light up or switch labels.