Researchers Find the Right Formula for Scalable Production of Material that Can Decontaminate Water, Advance Ultra-fast Light-based Computers

An international team of researchers has found a way to refine and reliably produce an unpredictable and hard-to-control material that could impact environmental conservation, energy and consumer electronics.

The material, Molybdenum Disulfide (MoS2), holds tremendous potential for numerous applications in energy storage, water treatment, gas, chemical and light sensing. But high costs and fabrication challenges have held back wider use.

“There are many different ways to fabricate this material, but no one has yet been able to make it in a controlled and tunable dimension in large quantities, in a low-cost, reproducible fashion,” said Donglei (Emma) Fan, an associate professor in the Cockrell School of Engineering’s Walker Department of Mechanical Engineering and Texas Materials Institute.

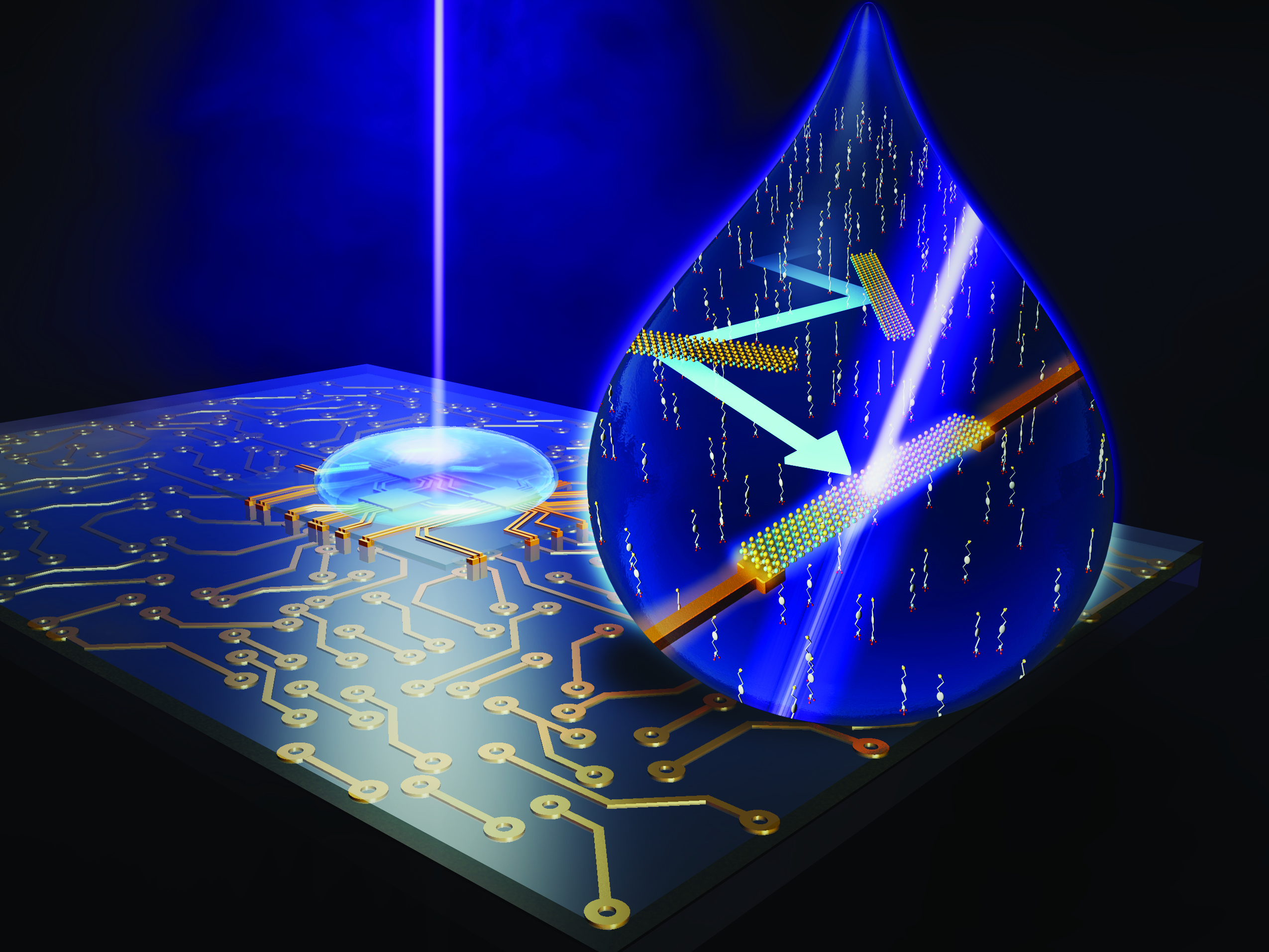

As reported in Advanced Materials, Fan and the research team have created a method to fabricate thin nanoribbons of MoS2 at a large scale. Previously, researchers were only able to make the material in small amounts and attach it at random to silicon substrates. This limited the material’s use, and when attached to the substrate, it became very challenging to manipulate.

The research team created a free-standing version of MoS2 in a powder form that can be dispersed into solutions for several different applications, most notably water treatment. Yun Huang, graduate student and first author of the work, said their process has cut the cost of fabricating a gram of the material by 3,000 times, compared to previous published research focused on producing MoS2 nanoribbons.

Removing the dangerous element mercury from water represents one of the most impactful uses of MoS2, Fan said. A 2016 study led by the U.S. Geological Survey found mercury contamination is widespread at various levels across the Western United States, in air, soil, sediment, plants, fish and wildlife. High levels of mercury can lead to brain and kidney damage, especially in younger people. Aside from contaminated water, humans are most exposed to mercury issues by eating fish, which can pile up high concentrations of the element in their bodies as they consume other organisms that have been exposed.

When introduced to water in powder form, the team’s version of MoS2 can be dispersed with the ability to suck up mercury and remove it from water. There are several methods for removing mercury from water already, but with these new low-cost and large-scale manufacturing capabilities, MoS2 makes for a strong alternative solution.

“This is an attractive material because it has unique properties for various applications with the potential to change people’s lives. Being able to make the material with controlled dimensions and in a large quantity, assemble it and integrate it with pre-made devices brings MoS2 a step closer to practical applications, not just staying in the lab,” Fan said.

MoS2 also has potential as a component in light-based microprocessors, which offer the promise of much faster computing speeds over today’s devices. It could also serve as a low-cost catalyst for generating hydrogen fuel from water.

Creating MoS2 is a challenge. It comes from adding sulfur to a morphed “pre-cursor” material. Splitting this process into two steps — first performing the sulfurization at a lower temperature and then upping the heat — represented one of the key innovations in making MoS2 more controllable.

The research team’s “spoonful” of MoS2.

Previous experiments making MoS2 nanoribbons have only been able to create a microscopic amount of the material. However, the researchers are able to obtain a “spoonful” of MoS2 nanoribbons with a single synthesis, and the researchers say there are no barriers to hold back scaling up the procedure to create larger quantities of the material.

MoS2 is part of a class of 2D materials that have received a lot of attention from researchers lately. They are thin, flexible and capable semiconductors, traits that make them valuable as part of sensors for everything from heart monitors to pollutant emission detectors.

The UT team includes Fan and her students – Huang, Huaizhi Li and Zexi Liang. Other team members include Peer Fischer from the University of Stuttgart and the Max Planck Institute for Intelligent Systems in Germany and his former postdoc Debora Walker from Harvard University; Kang Yu and his advisor Paulo Ferreira, an adjunct professor at UT who is also a professor at the International Iberian Nanotechnology Laboratory and University of Lisbon in Portugal; and Kai Xu from the University of Illinois at Urbana-Champaign.

The research was funded by the National Science Foundation and Welch Foundation, with travel support from the UT Portugal program.